Polymers/Resins/High Performance Chemicals

Metallocene-based PolypropyleneWintec™

Characteristics

■ Wintec™

| Generic name | Polypropylene |

| Abbreviation | PP |

| English name | polypropylene |

| Chemical formula |  |

| Crystalline/Amorphous | Crystalline (Tm:165℃) |

| Supply format | pallet, milk white, semitransparent (natural colour) |

■ Advantageous features

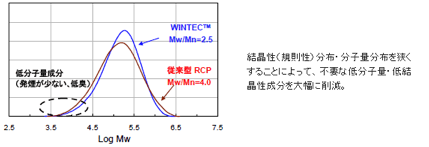

• Narrow crystallinity distribution.

Production of low melting point polymer is possible, in which rigidity/heat resistance commensurate with the melting point is kept high.

Excellent transparency.

• Few components with low molecular weight/low crystallinity.

With excellent resistance to solvent extraction, for moulded items with little smell/taste.

Low smoking/odor/mould staining when shaping, for a pleasant working environment and mass productivity.

Reduced surface contamination due to surface bleeding.

Reduced stickiness of surface.

• Narrow molecular weight distribution.

With low melt tension, for improved extensibility and ability to draft.

Uses

Wintec™ (metallocene-based polypropylene), with cleanness from greatly reduced low molecular weight impurities, is ideal for food and medical packaging. Also, with low surface contamination, it is used for secondary processing such as printing and deposition.

- Heat sealants, shrink films, overwrap packaging

- Food packaging and containers, transparent sheets

- Medical packaging/containers

- Secondary processing such as printing and deposition

- Fibres, meltblown, spunbonded

- Lamination, CPP etc. with improved production efficiency from high-speed processing

- Flexible, without stress whitening, for hinge caps.